- Home

- Products

- Hoses for Oil & Gas Sector

- Swaged Coupling Rotary and Vibrator Hose

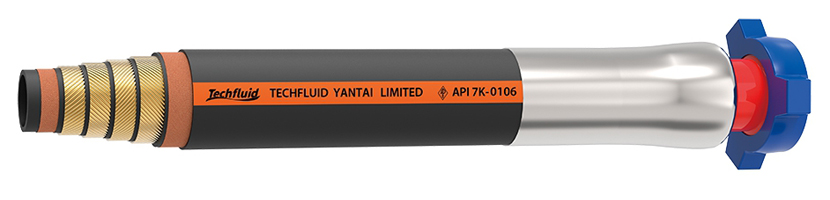

Swaged Coupling Rotary and Vibrator HoseType: NJG-SY / SNG-SY

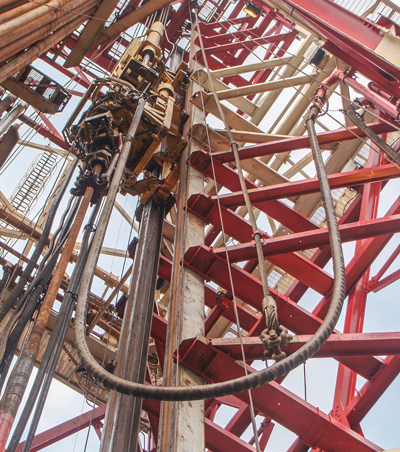

The slurry hose is used as a flexible connection between the drilling machine and the water faucet for vertical movement. This vibrator hose is also a flexible connection between a slurry pump and a vertical pipe. It is widely used to deliver high pressure slurry for cementing pumps.

API Spec 7K / ISO 6807 / GB/T 24145

7K-0458

Ⅱ level, -25 ~ +100 ℃

The normal hose structure satisfies SR6A standards and is able to maintain for 5 minutes in a 704℃ fire. With the addition of an outer fire insulation layer (glass fiber cloth) to the outer cover, the hose will meet SR6B standards for fire protection and maintain for up to 30 minutes in a 704℃ fire.

Composite rubber as the inner sealing tube, mainly composed of nitrile rubber with an excellent oil, seawater, and thermal resistance.

- Protective layer made of a high strength fabric cloth

- Skeleton material made of a high strength helix steel wire

- Composite rubber cover layer, made by chloroprene rubber for an excellent fire protection, oil, abrasion, ozone, and aging resistance

- Optional electric heating tracing feature

- Optional stainless-steel armored cover, stainless steel wire, or polyethylene helix cover according to specific requirements

- Flexibility Level: FSL2

- Maximum Length: 70m

- Production Length Tolerance: 6.4m or under ± 64 mm, above 6.4m ± 1%

- The minimum bending radius is measured according to the hose central line.

| Code No. | I.D. (inch) (mm) | O.D. (inch) (mm) | Working Pressure (bar) (psi) | Test Pressure (bar) (psi) | Flame Shield | Safety Factor | FSL | MBR (storage) (m) | MBR (operation) (m) | Weight (Kg/m) | Max. Length (m) | |||||

| NJG-SY-51×34.5 | 2 | 51 | 3.43 | 87 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 0.8 | 0.9 | 10.2 | 70 | |

| NJG-SY-64×34.5 | 2.5 | 64 | 4.02 | 102 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 0.8 | 0.9 | 13.6 | 70 | |

| NJG-SY-76×34.5 | 3 | 76 | 4.49 | 114 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.1 | 1.2 | 15.4 | 70 | |

| NJG-SY-89×34.5 | 3.5 | 89 | 5.16 | 131 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.2 | 1.3 | 20 | 70 | |

| NJG-SY-102×34.5 | 4 | 102 | 5.71 | 145 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.2 | 1.4 | 22.4 | 70 | |

| NJG-SY-127×34.5 | 5 | 127 | 7.52 | 191 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.4 | 1.5 | 47.8 | 70 | |

| NJG-SY-152×34.5 | 6 | 152 | 8.5 | 216 | 345 | 5,000 | 517 | 7,500 | No | 2.5 | FSL2 | 1.6 | 1.8 | 58 | 70 | |

| NJG-SY-51×51.7 | 2 | 51 | 3.9 | 99 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.1 | 1.2 | 18.2 | 70 | |

| NJG-SY-64×51.7 | 2.5 | 64 | 4.74 | 120.5 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.1 | 1.2 | 26.4 | 70 | |

| NJG-SY-76×51.7 | 3 | 76 | 5.28 | 134 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.2 | 1.3 | 30.2 | 70 | |

| NJG-SY-89×51.7 | 3.5 | 89 | 5.79 | 147 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.2 | 1.3 | 36.4 | 70 | |

| NJG-SY-102×51.7 | 4 | 102 | 6.3 | 160 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.3 | 1.4 | 40.4 | 70 | |

| NJG-SY-127×51.7 | 5 | 127 | 7.32 | 186 | 517 | 7,500 | 776 | 11,250 | No | 2.5 | FSL2 | 1.4 | 1.5 | 48.2 | 70 | |

| SNG-SY-51×69 | 2 | 51 | 3.9 | 99 | 690 | 10,000 | 1,034 | 15,000 | No | 2.25 | FSL0 | 1.1 | 1.2 | 18.2 | 70 | |

| SNG-SY-64×69 | 2.5 | 64 | 4.74 | 120.5 | 690 | 10,000 | 1,034 | 15,000 | No | 2.25 | FSL0 | 1.2 | 1.3 | 26.4 | 70 | |

| SNG-SY-76×69 | 3 | 76 | 5.28 | 134 | 690 | 10,000 | 1,034 | 15,000 | No | 2.25 | FSL0 | 1.3 | 1.4 | 30.2 | 70 | |

| SNG-SY-89×69 | 3.5 | 89 | 5.79 | 147 | 690 | 10,000 | 1,034 | 15,000 | No | 2.25 | FSL0 | 1.3 | 1.4 | 36.4 | 70 | |

| SNG-SY-102×69 | 4 | 102 | 6.3 | 160 | 690 | 10,000 | 1,034 | 15,000 | No | 2.25 | FSL0 | 1.3 | 1.4 | 40.4 | 70 | |

No. 628 PingLiDian Road, Laizhou City, Shandong Province