- Home

- Products

- Conveyor Belts

- Steel Cord Conveyor Belt

Steel Cord Conveyor Belt

Steel cord conveyor belts use steel wire for a higher power performance, making it ideal for use in mining transportation, metallurgical transportation, electric transportation, and chemical material transportation.

Features

- Excellent extension strength, making it suitable for long-distance transportation.

- Small elongation rate.

- Excellent blending of rubber and steel wire to enhance the conveyor belt strength.

- Great impact resistance, twist prevention characteristics

- Outstanding fatigability, allowing for a longer service life

- Smaller roller diameter, and stable performance.

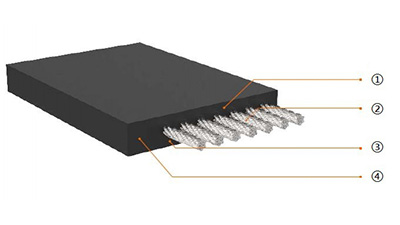

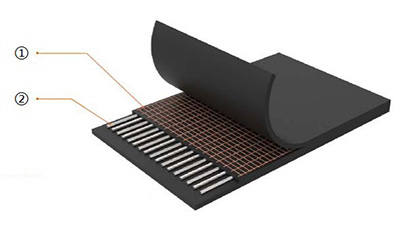

Construction:

① Upper cover layer

② Steel wire

③ Bottom cover layer

④ Side rubber

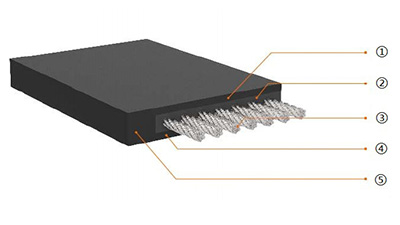

① Upper cover layer

② Core rubber

③ Steel wire

④ Bottom cover layer

⑤ Side rubber

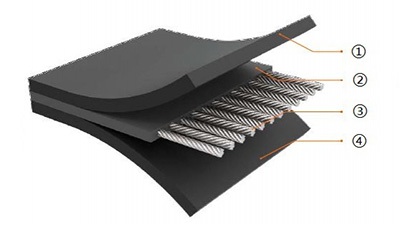

Tear Resistant Structure:

Based on the traditional version, we added steel cords and fiber cords perpendicular to the steel wire.

① Upper cover layer

② Core rubber

③ Steel wire

④ Bottom cover layer

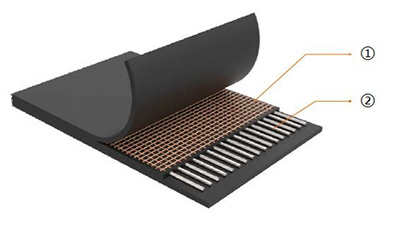

① Anti-tear steel cord

② Steel wire

① Anti-tear steel cord

② Steel wire

Technical Parameters:

ST Series| Code No. | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 | ST 6300 |

| Tension Strength (mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 |

| Steel wire diameter (mm) | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7.2 | 8.1 | 8.6 | 8.9/9.1 | 9.7 | 10.9 | 11.3 | 12.3 |

| Steel wire gauge (mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15/17 | 16 | 17 | 17 | 18 |

| Upper cover layer thickness (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 |

| Bottom cover layer thickness (mm) | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 |

| Width (mm) | Steel wire quantity | |||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | ||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64/56 | 59 | 55 | 55 | 54 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77/68 | 71 | 66 | 66 | 63 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90/79 | 84 | 78 | 78 | 74 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104/91 | 96 | 90 | 90 | 85 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117/113 | 109 | 102 | 102 | 96 | |

GX Series

| Code No. | GX 630 | GX 800 | GX 1000 | GX 1250 | GX 1600 | GX 2000 | GX 2500 | GX 3000 | GX 3500 | GX 4000 | GX 4500 | GX 5000 | GX 5500 | GX 6000 |

| Thickness | 6+7+6 | 7+9+7 | 8+11+8 | 8+12+8 | 8+13+8 | 8+14+8 | 8+16+8 | |||||||

| Tension Strength (mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 5500 | 6000 |

| Steel wire diameter (mm) | 4.5 | 4.5 | 4.5 | 4.5 | 6.0 | 6.0 | 7.2 | 8.3 | 8.7 | 9.1 | 9.7 | 10.9 | 11.3 | 12.3 |

| Steel wire gauge (mm) | 20 | 17 | 13.5 | 11 | 20 | 16 | 17 | 18 | 18 | 17 | 16 | 17 | 17 | 18 |

| Thickness (mm) | 19 | 19 | 19 | 19 | 23 | 23 | 27 | 28 | 28 | 29 | 30 | 30 | 32 | 32 |

| Width (mm) | Steel wire quantity | |||||||||||||

| 800 | 38 | 45 | 56 | 69 | 38 | 47 | 44 | 43 | ||||||

| 1000 | 48 | 56 | 70 | 87 | 48 | 60 | 56 | 53 | 53 | 56 | 60 | 56 | 56 | 54 |

| 1200 | 68 | 86 | 104 | 58 | 72 | 68 | 64 | 64 | 68 | 72 | 68 | 68 | 63 | |

| 1400 | 100 | 122 | 66 | 84 | 78 | 74 | 74 | 79 | 84 | 79 | 79 | 74 | ||

| 1600 | 116 | 140 | 76 | 95 | 90 | 86 | 85 | 90 | 96 | 91 | 91 | 85 | ||

| 1800 | 127 | 157 | 86 | 108 | 102 | 96 | 96 | 101 | 107 | 103 | 103 | 96 | ||

Recommended Mininum Roller Diameter

| Specification | ST630 ST800 | ST1000 ST1250 | ST1600 ST2000 | ST2500 | ST31500 | ST3500 ST4000 ST4500 | ST5000 ST5400 ST6300 |

| Min. Roller | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 |

| Specification | GX630 ST800 GX1000 GX1250 | GX1600 GX2000 | GX2500 | GX3000 | GX3500 GX4000 | GX4500 GX5000 | GX5500 GX6000 |

| Min. Roller | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 |

Other Products

Contact Us

No. 628 PingLiDian Road, Laizhou City, Shandong Province

Inquiry